Eco-Certified and Iso-Certified

Productions

Eco-Certified and Iso-Certified

Productions

In a state-of-the-art manufacturing site, quality is our greatest priority. Our production follows Pharmaceutical Standards (well beyond cosmetic), with very strict production and control procedures that comply with the EU Authorities & FDA.

Manufacturing Area

Vacuum kettles, ranging in size from 10-6.000 liters, provide the environment and technology for high quality, standardized products from batch to batch. In place a dedicated zone and equipment for flammables.

Annual product capacity of 5,500 tons of bulk

VESSEL I

Working capacity 1000lt, double jacket, CIP equipped, online connection, steam heated, vacuum operation. Two auxiliary vessels 1000lt each Produces creams, emulsions, conditioners and oils.

VESSEL II

Working capacity 2000lt, double jacket, CIP equipped, online connection, steam heated, vacuum operation. One auxiliary vessel 1200lt. Produces creams, emulsions, conditioners and oils.

VESSEL III

Working capacity 10lt, double jacket, online connection, vacuum operation, for small batch productions. Produces creams, emulsions, conditioners and oils.

VESSEL IV

Working capacity 6000lt, double jacket, steam heated, vacuum operation. One auxiliary vessel. Produces shampoos, shower gels, lotions, liquid soaps.

VESSEL V

Working capacity 200lt, double jacket, electrically heated, vacuum operation. Produces creams, scrubs, emulsions and oils.

VESSEL VΙ

Working capacity 400lt, double jacket, steam heated, vacuum operation. Produces creams, emulsions, conditioners and oils.

ALCOHOL VESSEL

Working capacity 200lt, double jacket with cooling. ATEX equipped. Produces mainly perfumes.

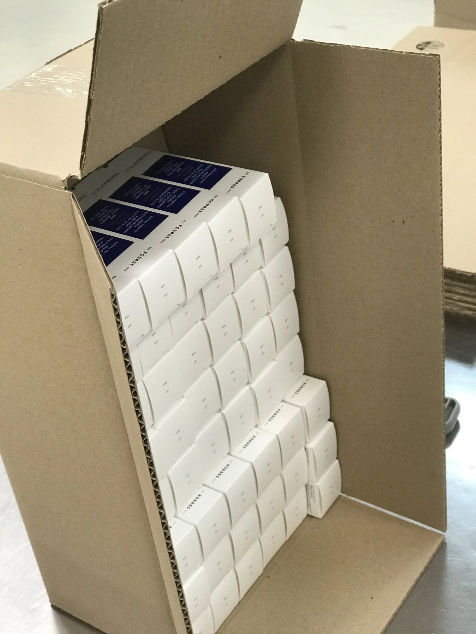

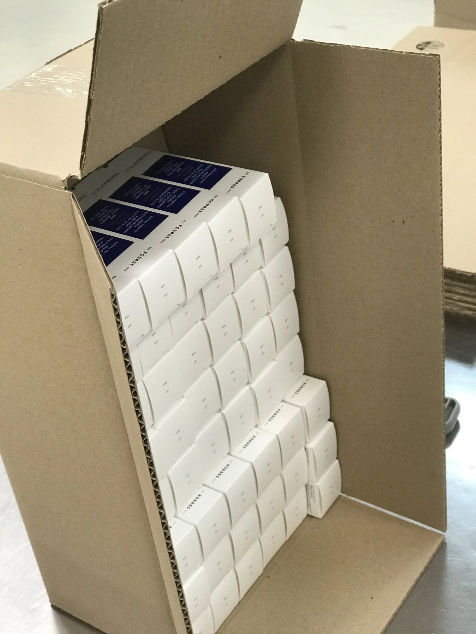

Filling / Packaging Area

42 Million pieces of packaging annually

Plastic bottles: 30-1000ml

(various caps e.g. flip top, screw, dosing pump)

Glass jars: 15-200 ml

Glass bottles: 3 10-200 ml

Plastic & Laminated tubes: 10-300 ml

Aluminum tubes: 40-100 ml

Plastic dispenser bottles: 20-150 ml

Sachets: 1-20 ml

Our Labs

Fully equipped physico-chemical lab

with HPLC, UV-VIS spectrometer, Karl Fischer, viscometers, pH meters.

Our lab can perform all cosmetics related testing for:

1) Raw material

2) Packaging material

3) Bulk

4) Final product

Two dedicated labs in microbiology

1) QC testing for raw materials,

2) QC testing for cosmetic products

3) Water testing , absence of water pathogens

4) Challenge testing as per EP, USP, other risk-based protocols

5) Microbial risk testing – your microbial concerns addressed in custom made testing protocols

MACHINE 1

Fully automated filling, labeling packaging & palletizing continuous line. Packs plastic bottles of shampoos and shower gels. Nominal output: 110 pcs/min

MACHINE 2

Fully automated filling, capping (under cap and cap), labelling, packaging & palletizing line. Fills plastic bottles & glass jars with creams, emulsions and oils. Nominal output: 50 pcs/min

MACHINE 3

Semi automatic filling machine. Fills plastic and laminated tubes, dispensers with a variety of viscous products. Nominal output: 60 pcs/min

MACHINE 4

Semi automatic filling machine. Fills plastic and aluminum tubes with a variety of viscous products Nominal output: 30 pcs/min

MACHINE 5

Semi automatic and labelling machine. Fills plastic and glass bottles with shampoos, shower gels, body oils, deodorants and emulsions. Nominal output: 25 pcs/min

MACHINE 6&7

Two (2) manual filling machines All type of products.

MACHINE 8

Automated filling machine Fills plastic and multi layer sample sachets with a variety of products Nominal output: 120 pcs/min

MACHINE 9

Semi automatic horizontal cartoning machine. Nominal output: 60 pcs/min

The department is also equipped with numerous dosing pumps, carton printing, injects and labeling machines.

MACHINE 10

Semi automated vertical cartoning machine. Nominal output: 30 pcs/min

MACHINE 11

Fully automatic wrapper machine for full wrap of parallelepiped products for heat sealable films from reel (cellophane, PVC, polypropylene)

Our Labs

Fully equipped physico-chemical lab

with HPLC, UV-VIS spectrometer, Karl Fischer, viscometers, pH meters.

Our lab can perform

all cosmetics related testing for:

1) Raw material

2) Packaging material

3) Bulk

4) Final product

Two dedicated labs in microbiology

1) QC testing for raw materials,

2) QC testing for cosmetic products

3) Water testing , absence of water pathogens

4) Challenge testing as per EP, USP, other risk-based protocols

5) Microbial risk testing – your microbial concerns addressed in custom made testing protocols

Water Quality

A treatment for purifying water to the standards arma-grade water for production as per American Pharmacopeia is in place, combining the technologies of reverse osmosis and electrical deionization purification methods, rendering the water to purification levels of

less than 1μS in Conductivity, 5 times less than the European Pharmacopeia requires for Pharmaceutical Grade Products.

The purified water produced in the DISTRICT BOTANICA facility is stored in a 10.000lt, 316 stainless steel tank, providing a continuous flow of Purified Water to the manufacturing kettles. Vigorous testing is performed on a daily basis for chemical, microbial and operational performance to verify the water’s properties remain stable and up to the highest standards.

Certifications

EOF_ GREEK ORGANIZATION FOR MEDICINES

KORRES SA is a licensed manufacturer for cosmetics and drugs by GREEK ORGANIZATION FOR MEDICINES.

ISO CERTIFICATIONS (current versions) •

QUALITY Management (ISO 9001) • ENVIRONMENTAL Management (ISO 14001) • GMPs (ISO 22716)

IFS HPC CERTIFICATION (Higher level)

Categories

Face care

Body care

Fragrance

Hair care

Sun Care

Kids Baby Care

Mens Care

Packaging Options

Glass Jars: 15 - 200ml

Plastic Bottles: 30 - 1000ml

Glass Bottles: 10 - 200ml

Plastic & Laminated Tubes: 10 - 300ml

Aluminum Tubes: 40 - 100ml

Plastic Dispenser Bottles: 20 - 150ml

Sachets: 1 - 20ml

Types of Formulas

Creams

Emulsions

Lotions

Serums

Masks

Scrubs

Shower gels

Oils

Shampoos

Conditioners

Liquid Soaps

Toothpastes

Fragrances